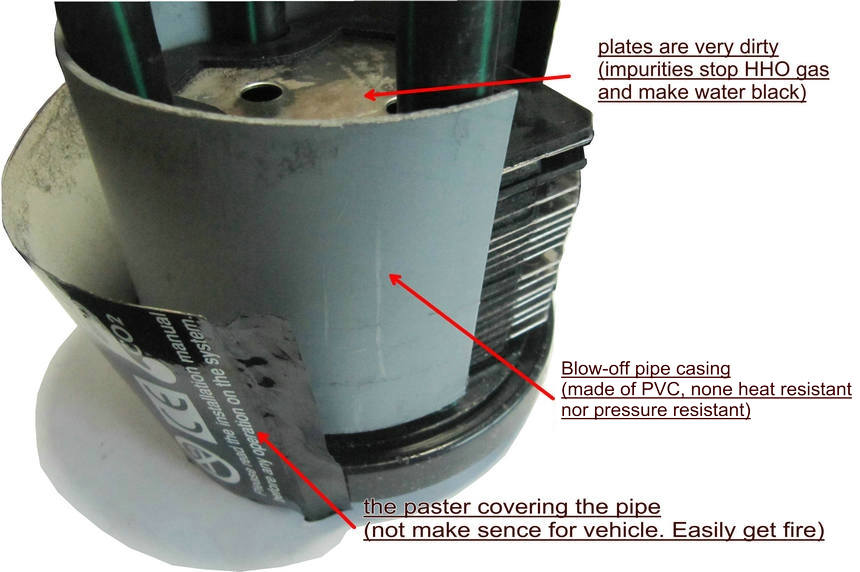

1, OGO got a cell made by other HHO kits provider from a client. This cell declared made in EUR and good selling. Client asked us to test because he had some doubt. OGO Test Room open the endplate and shocked.

2, "OK, let's struggle on"

--Dusts covering on the plates. Electroconductivity is high and HHO gas production reduced.

--PVC water pipe casing is very easy damage and none heat or pressure resistant

--Paster covering the pipe to make it better looking but it is not fireproofing tap. Just the reverse, it is made of fire goods. Totally not make sence.

3, Another view under highlight. Dusts and dirties, gaskets and plates are not in order.

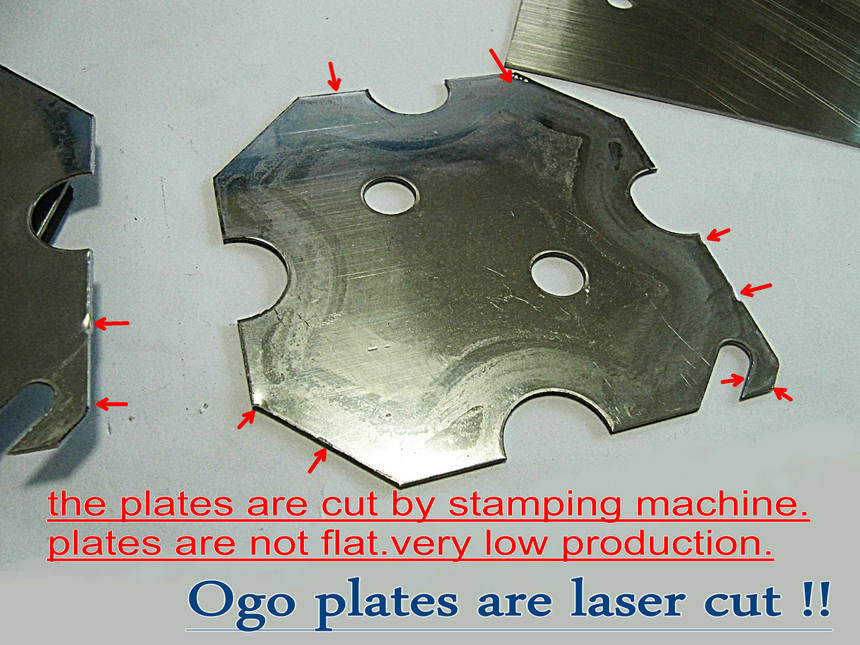

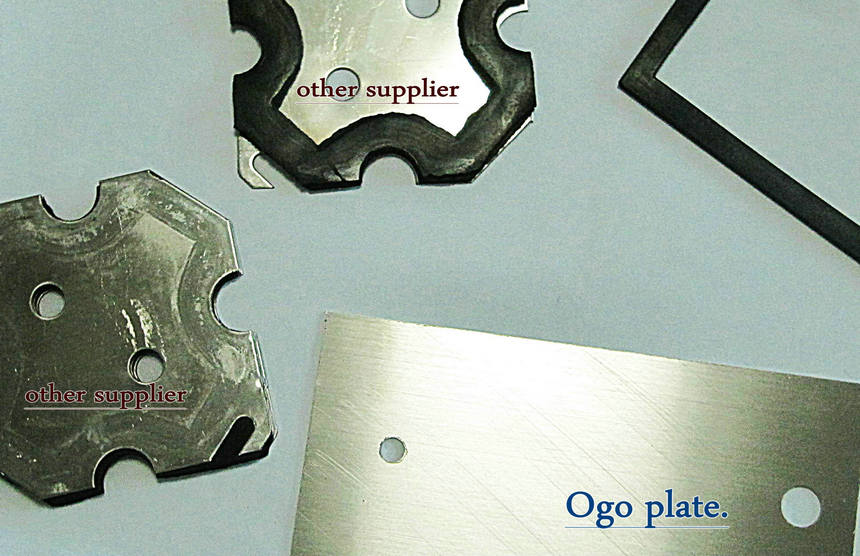

4, Take off a gasket and found it is a low quality and poorly made by stamping machine

5, Let't see OGO gasket

6, Take a plate off and found it was badly made.

7, A comparing view. OGO plates are made by laser cutting machine.

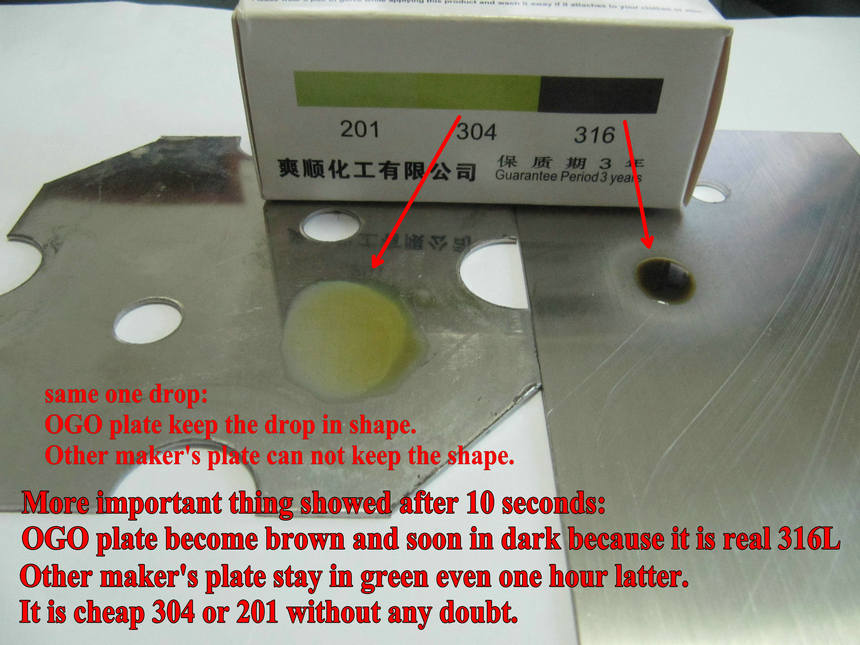

8, Use some special testing reagent and found the result is disappointed. 10 seconds latter, the truth is turning out.

--The reagent turn in to brown very soon on OGO plate, while no change on other supplier's plate.

--OGO plate is rough surface made by laser machine, thus to make more HHO gas generated. Therefore, OGO plate can keep the reagent in shape. Other supplier's plate is smooth surface and not flat on the table. Therefore, the reagent can not keep in shape.

9, If it is 316, the color will be brown as the reference picture. OGO plates are 316L and it is even deeper brown, almostly in black color.

--10 minutes latter, the reagents is obviously telling the differences.

10, After one hour's test, the client is disappointed of the cell from other supplier.

* This result is only refer to the cell provided by the client to OGO Lab.

OGO promise to make the best for HHO. Here is an OGO dustfree room entry and a window to see workers assembling Cells.